| This is a pressure tester that we made for

the purpose of checking a blow torch tank and pump. The tank can be pressurized either with

the pump on the tank, or by attaching an air hose to the valve stem connector that appears

at the end of the copper fittings. Any leaks can be detected by watching the pressure guage

over time; any decrease in tank pressure indicates a leak someplace. The most common source

for air leaks is in the pump check valve. it is common for the check valve in these old blow

torches to fail to seal. |

| This is a closeup of the valve stem assembly

from our tank tester. This is not a critical assembly in that it is made up using whatever

plumbing fittings are available. The diameter employed is a function of the diameter of the

valve stem. It is vitally important that the assembly be air tight for obvious reasons. There

are many ways in which a common valve stem could be connected to the 3/8 inch pipe used for the fuel delivery in a common

blow torch. This particular one was made out of copper pipe fittings. It could just as

easily been

made with PVC pipe fittings. Copper however, has the advantage that the connections can be

reheated if ther is a leak during assembly testing. |

| This is a close up of the air pressure guage on our

blow torch tank pressure tester. The tank is brought up to about 30 PSI and allowed to sit

for several hours to determine by how much the pressure decreases with time. The less

perssure loss, the better. There will be some leakage, and it is not a problem until the

leak gets so bad that the torch will fail to burn the entire tank of gasoline without

repressurizing the tank. The pressure testing device, previously mentioned, is intended to

be a diagnostic tool as opposed to a device for taking quantitive measurements. |

| There are many occasions where it is necessary to

clear a small obstruction from some location in a blow torch. here is a common dental pick

that is available at most flea markets. this particular one has a very sharp point which

makes it handy for digging out the sealing compound in a check valve or for digging out the

packing string from a packing nut. This tool can be used to clean out a plugged orifice if

the technician is very careful not to enlarge the orifice in the process. Every blow torch

tool kit should have one or more dental picks of different sizes. |

| This is a very simple device that was made

to clean out the burner head undervein and the valve stem nest. It is fashioned from a common

pin vise available at most hardware stores, and a small twist drill. There are many times

when it is helpful to have a means for lightly drilling away an obstruction. This tool can

be used to help free up a rotted wick so it can be removed from the wick tube. This tool is

helful in clearing away any carbon build-up in the burner head undervein. |

| A pipe wrench is an essential item for blow

torch restoration. A fairly small one like the one pictured here, is plenty good for most

torch disassembly operations, It is usually wise to place the burner head in a vise and

rotate the tank until the the wick tube can be unscrewed from the tank. The pipe wrench is

then used to free the wick tube from the burner head. |

| Steel wool is very helpful in

restoration and repair work on old blow torches. It is good practice to clean all parts

removed with steel wool to break loose any particles that potentially may later plug the

torch. The wick

tube can be made brightely clean with the use of steel wool. Tanks can be cleaned to reveal

any cracks or rust-through situations commonly fond on the bottom of some torches. |

| Here pictured is a common thread guage. It is

occasionally neccessary to replace the brass portion of a two-part wick tube. The thread

guage is used to determine the required thread pich for the replacement wick tube or for

other threaded component. |

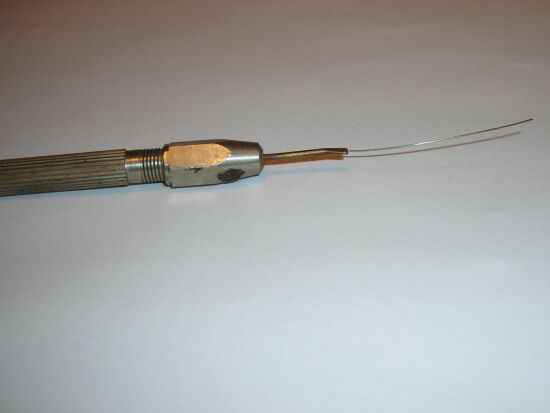

| This is an interesting device made with a pin

vise and small diameter brass model tubing. A notch is cut into the end of the brass to hold

the end of the spring wire. The wire is then wound up on the brass for the required number of

turns.This

device is used for rewinding replacement springs for a check valve. The diameter of the

tubing used is a function of the size spring being replaced. |

| Installing the wick tube and burner head

assembly back into the tank can be challenging sometimes. This is because the wick strings

can be difficult at times to cram back into the tank in an orderly manner. This neat tool was

made

to simplify that process by providing a means to poke the wick strings into the tank fuel

nipple fitting. The

device was made from an old screw driver. First, the old blade was cut off and the end of

the secrewdriver shaft was ground flat; the screwdriver shaft then had the appearence

of a drill rod with a handle on it. Then we used a grinding wheel to cut a notch in the

shaft as close to the end as possible. Then we bent a finishing nail into a U-shape and

brazed it to the notch we just ground. Thus, the device has a uified appearance. We've used

this little tool on several occasions and it has saved a lot of frustration and time.

Basically, you put the wick strings into the "U" then push the wick strings through the

wick tube fitting and then into he tank. |

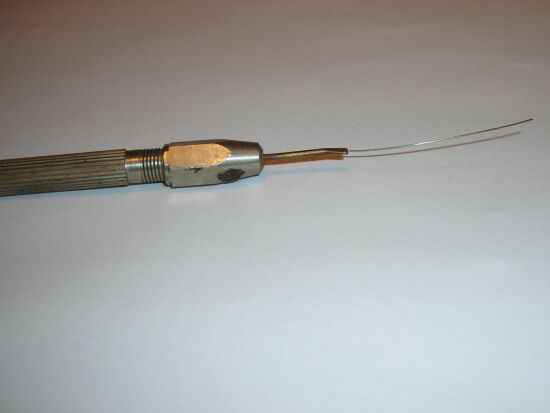

| This tool was made from a small size

piece of brass model tubing and some .014 music wire. The brass tubing was then crimped, much

like you would do in attaching a spade lug to a wire, over the music wire. You must use care not

to crimp so tight that it results in breaking the music wire. The crimp has to be tight enough to

reliably hold the music wire. Any tighter than what is required, is overkill.This assembly is

then chucked up into

the other end of the pin vise referred to earlier. This is used to clean out plugged

orifices. This particular size music wire is the same diameter as a gasoline blow torch

orifice, and can therefore double as a circular feeler guage to determine if an orifice is

enlarged or if the orifice is sized for gasoline, fuel oil, etc. Sometimes you may have

what you thought was a gasoline torch only to find that it is really a kerosene torch. There are

times when the only way to be sure is by measuring the diameter of the orifice. Alcohol and

gasoline miniature torches are often confused. Sizing the orifice diameter can reveal which kind

of torch you have, along with other clues that are related to the way the burner head itself is

made. |

| This common hand held paper punch is handy for preparing

replacements for

worn out pump leathers. These punches are available at most office supply stores and are very helpful

for making a clean hole in the middle of a new pump leather. A good quality paper punch

should be purchased so it will make consistent, good quality holes and so it will give a

reasonable amount of service reliability. It does not have to be a fancy one; they do need

to be

reliable. |

| This little brush was made for cleaning out the

undervein on a blow torch burner head. The bristles were pulled from a small wooden wire

brush that was a bit bigger than a tooth brush. The shaft of the brush is a small

length of brass model tubing. The size is not critical so long as it affords reasonable

strengh and it is small enough to fit into the undervein passage. This tool is helpful

for breaking free stubborn carbon deposites from the wall of the undervein. |

| Here is a modest collection of stiff plastic-bristle

brushes. They can be found at hardware stores, specialty tool suppliers and flea markets.

These brushes are used for performing the final cleaning of the undervein. These particular

brushes are modified versions of the original brushes in that, the original brushes had a

straight shaft with a loop at the end. The loop was cut off and the shaft was then bent into a

crank shape as shown here. This allows the brush to be rapidly rotated by turning the crank.

A version of these brushes have occasionally been modified so they can be chucked

up in an electric drill. Care must be taken so the brush shaft does not become twisted and

wrap itself around your work, or around fingers and hands. Extreme care must be used when

using power tools around old gasoline blow torches. |

| This is a distant shot of our pin vise with a drill

at one end and the orifice cleaner at the other. A close-up of each end appears elsewhere

on this page. |

| Here is a dental pick that has been

modified. The sharp probe end was broken off and then ground down with an electric grinder

which results in a short, but larger diameter pin at the end. This modified dental pick was

made for

cleaning out the end of the air pump where the check valve stem seal hits it. Over a long period

of time, the sealant material in the check valve stem can plug the end of the air pump when

it eventually rots. This device provides a safe way to ream out the air pump hole to clear

out any debris that may have collected there over time. |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |